READ MORE

-

Flache & einstellbare "Metallinsen" jetzt einen Schritt näher an der Realität

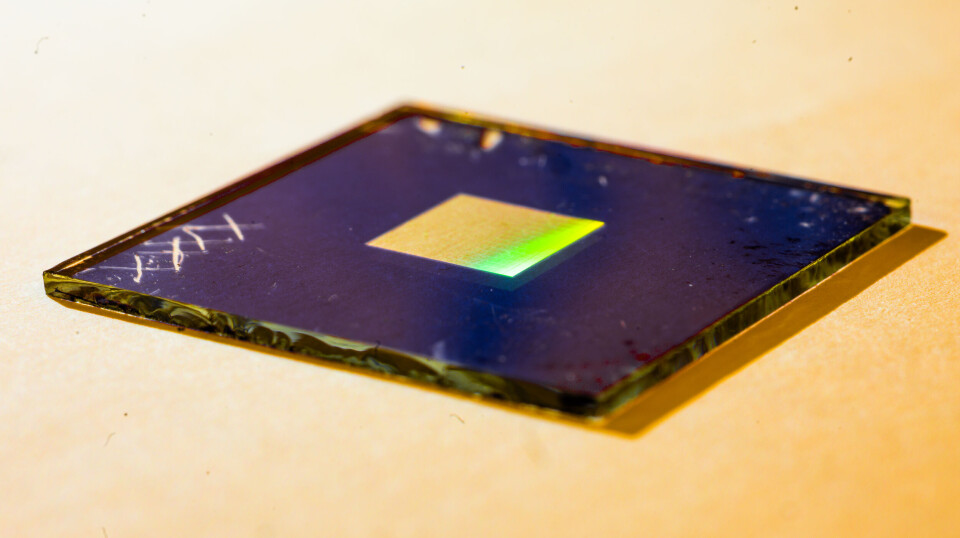

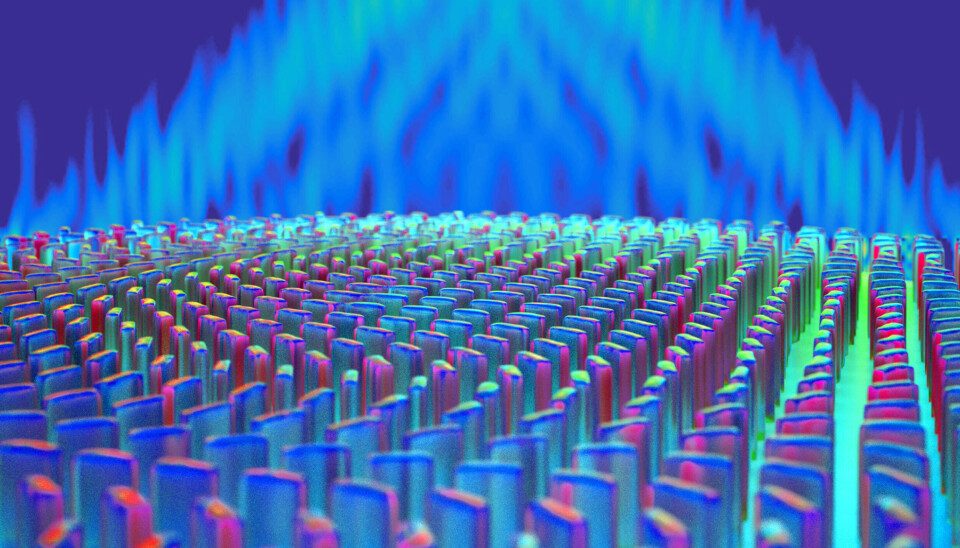

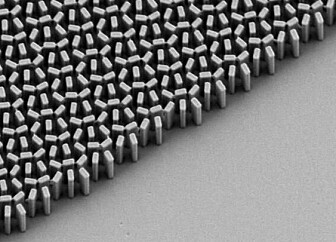

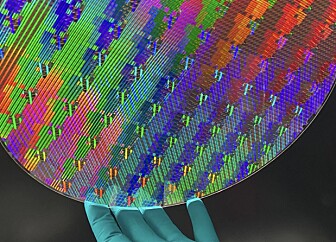

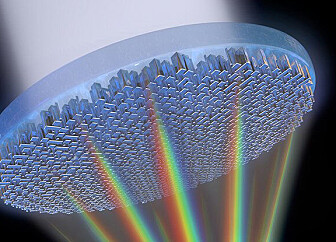

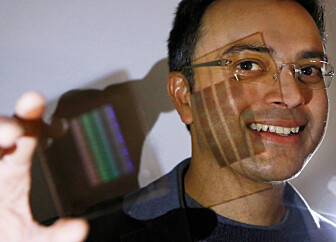

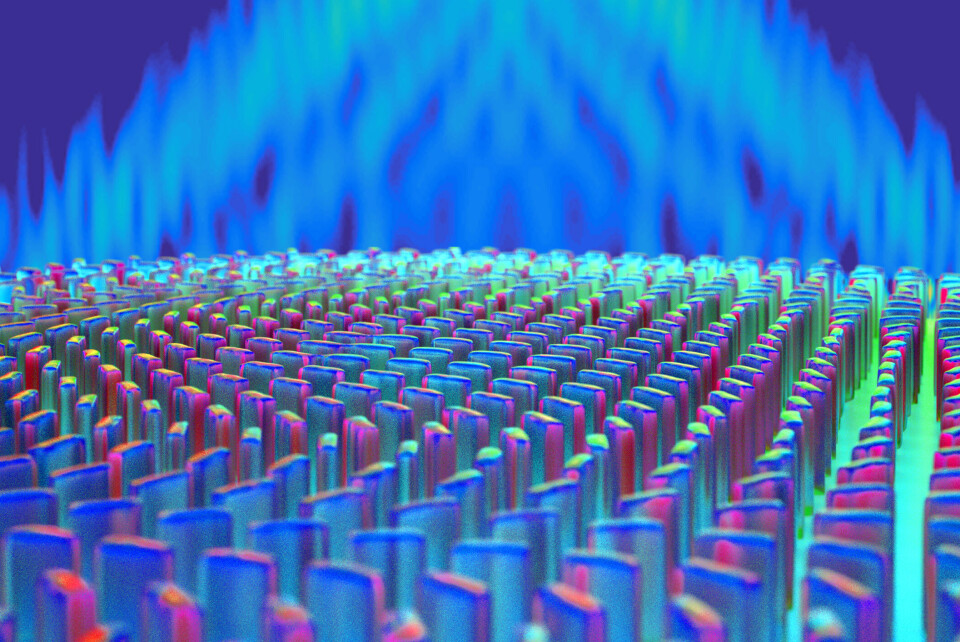

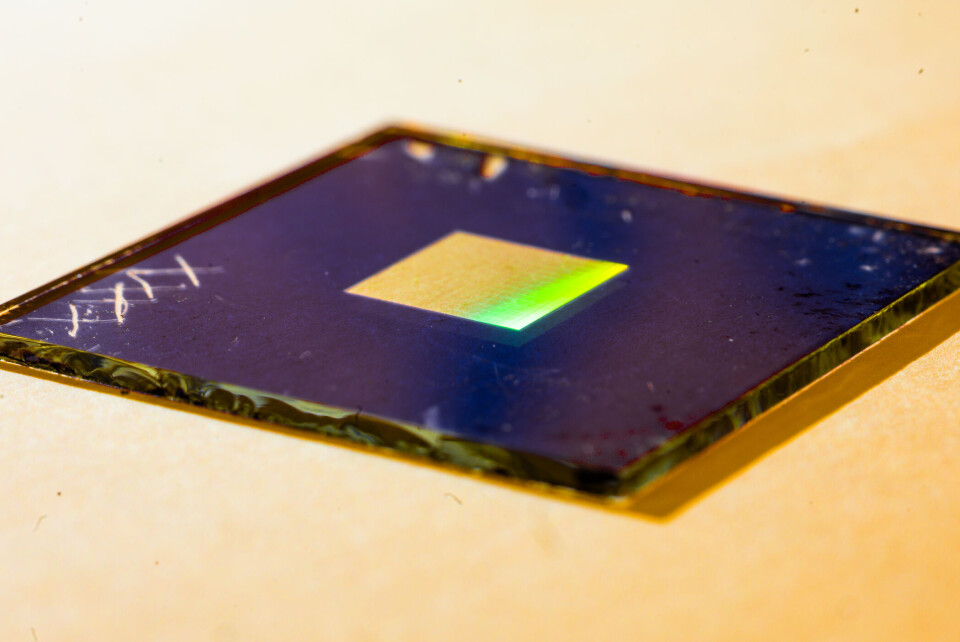

Forscher der Universität Linköping haben optische Metaflächen in leitfähigem Kunststoff entwickelt, die in Sensoren, biomedizinischer Bildgebung, Videohologrammen und letztendlich auch in Kameras verwendet werden können.

-

Lentilles "métalliques" plates et ajustables désormais un pas plus près de la réalité

Des chercheurs de l'université de Linköping ont développé des métasurfaces optiques en plastique conducteur pouvant être utilisées dans des capteurs, l'imagerie biomédicale, les vidéohologrammes et finalement aussi dans les caméras.

-

Flade & justerbare "metalinser" nu et skridt nærmere virkelighed

Forskere ved Linköpings universitet har udviklet optiske metaflader i ledende plast, der kan anvendes i sensorer, biomedicinsk billeddannelse, videohologrammer og i sidste ende også kameraer.

-

Litteät & säädettävät "metalinssit" nyt askeleen lähempänä todellisuutta

Linköpingin yliopiston tutkijat ovat kehittäneet johtavasta muovista valmistettuja optisia metapintoja, joita voidaan käyttää antureissa, biolääketieteellisessä kuvantamisessa, videohologrammeissa ja lopulta myös kameroissa.

-

Flate & justerbare "metalinser" nå et steg nærmere virkelighet

Forskere ved Linköpings universitet har utviklet optiske metayter i ledende plast som kan brukes i sensorer, biomedisinsk avbildning, videohologram og til slutt også kameraer.

-

Lentes "metálicas" planas y ajustables ahora un paso más cerca de la realidad

Investigadores de la Universidad de Linköping han desarrollado metasuperficies ópticas en plástico conductor que pueden usarse en sensores, imágenes biomédicas, videohologramas y, en última instancia, también en cámaras.

-

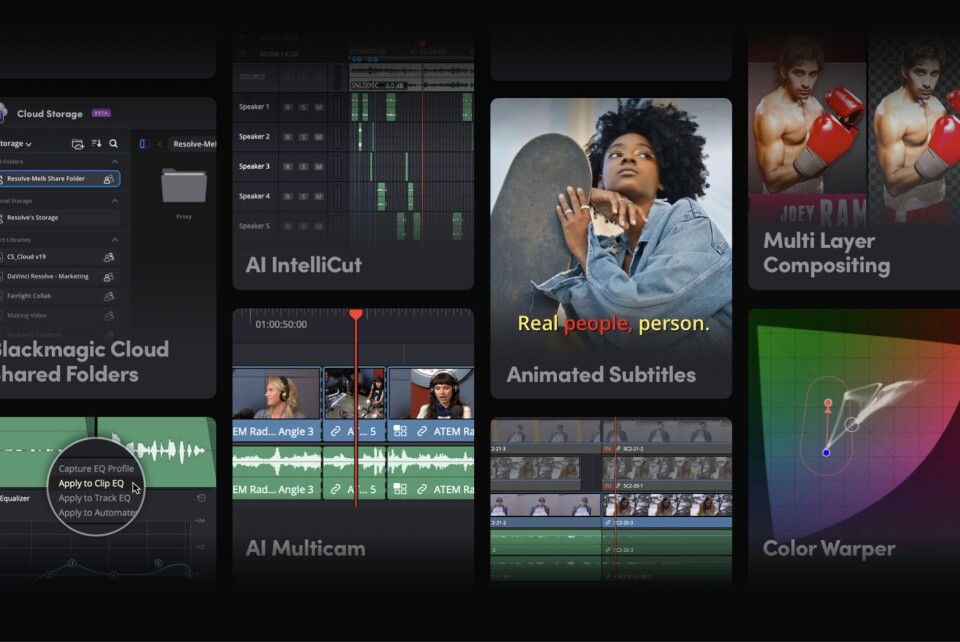

DaVinci Resolve 20 lansert - med over 100 nye funksjoner

Den store versjonsoppdateringen inneholder blant annet DaVinci AI-verktøy, keyframe editor, voice over-paletter, multi-lags komposisjon, pluss chroma warp og Magic Mask 2.

-

DaVinci Resolve 20 julkaistu - yli 100 uutta ominaisuutta

Suuri versiopäivitys sisältää muun muassa DaVinci AI -työkaluja, keyframe-editorin, voice over -paletit, monikerroskompositoinnin, sekä chroma warpin ja Magic Mask 2:n.

-

DaVinci Resolve 20 udgivet - med over 100 nye funktioner

Den store versionsopdatering indeholder blandt andet DaVinci AI-værktøjer, keyframe editor, voice over-paletter, multi-layer komposition, plus chroma warp og Magic Mask 2.

-

Sony lanserer kameragrepet & fjernkontrollen GP-VPT3/RMT-VP2

Sony slipper nå dingser som hjelper den som vil forenkle sin filming eller fotografering med enkle midler, samt en fjernkontroll for å styre kameraet på avstand.

-

Sony lancerer kameragrebet & fjernbetjeningen GP-VPT3/RMT-VP2

Sony udgiver nu gadgets, der hjælper dem, der ønsker at forenkle deres filmning eller fotografering med enkle midler, samt en fjernbetjening til at styre kameraet på afstand.

-

Sony lanseeraa kamerakahvan & kaukosäätimen GP-VPT3/RMT-VP2

Sony julkaisee nyt laitteita, jotka auttavat yksinkertaistamaan kuvaamista tai valokuvaamista yksinkertaisin keinoin, sekä kaukosäätimen kameran etäohjaukseen.

-

Nikon Short Film Award 2025: Here is the jury - submit your entry

Sofia Kappel, Daniel Espinosa, and Nanna Blondell are the jury for this year's edition of the film competition with the theme "Better Together".

-

Nikon Short Film Award 2025: Her er juryen - send dit konkurrencebidrag

Sofia Kappel, Daniel Espinosa og Nanna Blondell er juryen i årets udgave af filmkonkurrencen med temaet "Better Together".

-

Nikon Short Film Award 2025: Tässä on tuomaristo - lähetä kilpailutyösi

Sofia Kappel, Daniel Espinosa ja Nanna Blondell ovat tämän vuoden elokuvakilpailun tuomaristo teemalla "Better Together".

-

Nikon Short Film Award 2025: Aquí está el jurado - envía tu participación

Sofia Kappel, Daniel Espinosa y Nanna Blondell son el jurado en la edición de este año del concurso de cine con el tema "Better Together".

-

Nikon Short Film Award 2025: Her er juryen - send inn ditt bidrag

Sofia Kappel, Daniel Espinosa og Nanna Blondell er juryen i årets utgave av filmkonkurransen med tema "Better Together".

-

Nikon Short Film Award 2025 : Voici le jury - envoyez votre participation

Sofia Kappel, Daniel Espinosa et Nanna Blondell sont le jury de cette édition du concours de films sur le thème "Better Together".

-

Nikon Short Film Award 2025: Hier ist die Jury - reichen Sie Ihren Wettbewerbsbeitrag ein

Sofia Kappel, Daniel Espinosa und Nanna Blondell sind die Jury der diesjährigen Ausgabe des Filmwettbewerbs mit dem Thema "Better Together".

-

Fujifilm X half X-HF1 - analog følelse inspireret af halvformat

Det nye kamera er inspireret af analoge halvformatskameraer og har flere funktioner, der bygger på følelsen af netop analog fotografering.

-

Fujifilm X half X-HF1 - analoginen tunne inspiroitunut puolimuodosta

Uusi kamera on saanut inspiraationsa analogisista puolimuotokameroista, ja siinä on useita toimintoja, jotka perustuvat juuri analogisen valokuvauksen tunteeseen.